|

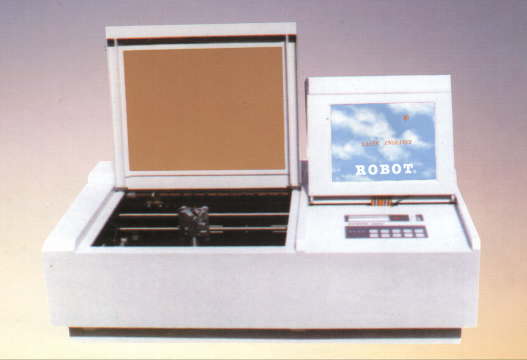

In your Coral files that are exported to the engraver

application program, resolution is one of the variables

that determine image quality when engraving on the Robot

® K600 Laser Engraver.

Resolution is expressed in dots per inch (dpi) and is

determined by the number of lines or dots that are engraved

for every inch of movement. Each horizontal line is referred

to as a raster line. The higher the resolution, the finer

the detail that can be achieved. Keep in mind that engraving

resolution is only one factor in determining image quality.

The quality of the artwork being sent to the laser can

have a bigger influence on the look of the final product

than the resolution. If low quality artwork is sent to

the laser system, even the highest resolution will not

improve it. Also keep in mind that image quality is subjective.

300 dpi may be just fine for some images and some customers,

while 600 dpi is the absolute minimum for others.

Most importantly, the size and the dpi

of the original image are interdependent, and these together

with the size of the engraved output image are related.

Think of it as - the amount of information in the original

image has to be transfered to the engraved output image.

75 - 150 - 200 dpi - These resolution

values are typically used for non-production purposes

where you want to experiment with image location, or if

you want to quickly produce a rough draft.

300 dpi - This resolution can be

good for production work where image quality needs to

be good, but not great. Many users will use 300 dpi on

plastic and other materials that don't require a lot of

power in combination with large block lettering. Attempting

to produce really fine detail with 300 dpi is not recommended.

400 dpi - This resolution value

is ideal for many applications. It combines very good

image quality with fast engraving times. Many users like

400 dpi for all of their work.

600 dpi - When really fine detail

or overall excellent results are required, most users

choose 600 dpi.

There are several things worth noting:

· There are four times as many dots engraved at

600 dpi than there are at 300 dpi - twice as many horizontally

and twice as many vertically.

· The gap between the dots is greatly reduced at

600 dpi. At 300 dpi the lesser overlap is responsible

for the jagged edges that are visible when engraving at

lower resolutions. It's important to remember that while

resolution plays a part in producing good image quality,

the artwork that is sent to be engraved is just as important.

If the artwork that is sent to the laser is poor quality,

trying to engrave it at 600 dpi will not improve it. It's

always best to start with high resolution images. Poor

artwork will probably always look poor at any resolution,

while good artwork will look good at any resolution.

· Twice as many dots and twice as many lines at

600 dpi produces a much deeper burn into materials like

wood than you would see engraving the same image at 300

dpi. This is important to understand because depth of

burn is closely associated with engraving resolution -

the higher the resolution, the greater the depth of burn

for a given speed.

The relationship between resolution, depth of engraving,

speed, power setting and size of image is something that

most people figure out with just a little experience.

· Changing resolution does not change the spot

size. Resolution only changes the spacing between dots.

For most applications, simply increasing the resolution

is the preferred method of improving image quality.

· The greater the resolution, the slower the engraving.

(Start with 300 dpi)

|